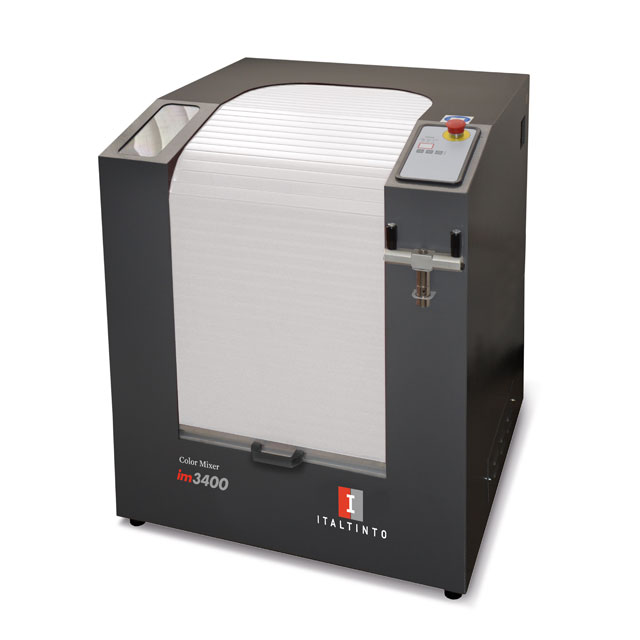

Il sistema tintometrico Eliocolor Performnce vi da accesso ad infinite tonalità di colore ottenendo soluzioni cromatiche innumerevoli. Scoprite la magia del colore.

Il sistema Eliocolor Performance vi consentirà di scegliere tra più di 20.000 tinte idonee a prodotti sia per interni che per esterni, garantendovi sempre la massima qualità.

Qualunque sia il colore che sceglierete, esso sarà realizzabile direttamente presso il punto vendita con il più alto standard di fedeltà cromatica. Anche a distanza di tempo potrete richiedere una tinta già utilizzata poiché il nostro sistema vi garantirà la sua assoluta ripetibilità e fedeltà cromatica.

Il sistema tintometrico del Colorificio Giuseppe Di Maria, denominato “Eliocolor Performance”, consente di ottenere prodotti vernicianti finiti, di qualità elevatissima, in tutta la gamma possibile di colori.

L’apparecchiatura del sistema tintometro Eliocolor Performance, viene gestita tramite un software persanalizzato, caratterizzato da una interfaccia intuitiva e alla portata di tutti.

L’apparecchiatura del sistema tintometro Eliocolor Performance, viene gestita tramite un software persanalizzato, caratterizzato da una interfaccia intuitiva e alla portata di tutti.

Ogni informazione relativa al processo di creazione di una tinta, viene visualizzata con chiarezza e immediatezza.

For any doubts or to request more information on the products of the Di Maria paint shop, call the toll-free number 800.523343

For any doubts or to request more information on the products of the Di Maria paint shop, call the toll-free number 800.523343 The procedure is as follows:

1. DECONTAMINATION AND BONIFYING PHASE

Apply Bisaten Detergent directly to the infested wall and surrounding areas with a brush; allow at least 8 hours for the biocides in the Detergent to destroy the micro-organisms, after which use a brush or wet sponge to remove all fluorescence and rinse with running water.

2. PREPARATION OF THE SURFACE

Using a brush, apply Bisaten Fixative diluted with water at a ratio of 1 to 2 (Lt 2.5 of Bisaten Fixative and Lt 5 of water) to all surfaces to be treated; wait approximately 4 hours before painting.

3. PROTECTION phase

Choose between the semi-gloss Bisaten version for a satin appearance, the matt Bisaten version for a non-glossy appearance like normal water-based paints or the much more porous and matt Bisaten 2000 version.

Yes, as long as it is well anchored after a coat of Bisaten Fixative

Yes, by applying, in several coats, a specific product such as Bisaten Anticondensa composed of hollow microspheres that make the final effect rustic. To obtain the desired colouring, simply add the dye and mix well before use.

Applying the special Bisaten Anticondensa coating generates a resistant finish on both ceilings and walls of rooms such as bathrooms, kitchens, breweries, food-packing factories, dairies, indoor swimming pools, etc.

In order to optimise the anti-mould and anti-condensation result, it is recommended in all cases to apply three coats after the immunising treatment with Bisaten Cleaner and Bisaten Fixative.

It is advisable to clean the floor and restore the joints with a cement “slurry” and allow it to dry thoroughly. Finally, treat the affected area with a transparent siloxane product such as Eliosil W119 in several coats, which will give it water repellency and walkability.

The most concrete advice is to make the bricked surface water-repellent by treating it with a saturating silicone resin as follows:

1. prepare a liquid hoe of water and cement and apply it with a rag on the surface so as to fill and saturate all existing cracks, paying attention to the joints between the bricks;

2. after it has completely dried, wipe off any loose material remaining on the surface with a dry rag, without wetting it further;ù

3. apply an abundant coat of Eliosil W119 (transparent water-repellent protective coating) with a brush

4. repeat the same operation a few more times until it is completely saturated, allow the solvent to evaporate and when the resin is completely dry (3-4 days) you can check the effectiveness of the treatment using the drop of water system: a meniscus will form and the brick will no longer absorb.

It is essential to ascertain that the cause is absorption of the building substrate and not infiltration caused by cracks in the plaster. In this case, it will be necessary to restore the surface before applying any product. Once this has been done, it is advisable to apply several coats of Eliosil W119 (approx. ½ litre/m2 ), which is totally breathable and water-repellent. It penetrates by reacting with moisture to form a solid inorganic compound that bonds to the treated building material, becoming a single body

Applying Eliover 080 elastomeric liquid sheathing. This is a permanent plastic waterproofing, consisting of acrylic resins and slow-migrating plasticisers that provides total water repellency to all treated surfaces of whatever nature. It withstands temperatures from -30°C to + 40°C without deterioration.

The recommended operating sequence is as follows

1. remove the existing enamel using Visola 1° paint stripper, which has been abundantly deposited on the surface already placed on a horizontal trestle surface;

2. clean the entire surface with White spirit;

3. fill the damaged parts with Eliomastick wood filler and then sand down;

4. apply a coat of Novalite cementite over the entire surface and re-sand with fine sandpaper

5. apply a first coat of Eliofinish One Coat synthetic enamel (of the desired colour) and after drying apply a second coat.

The suitable product is called Eliomare 110, available in white, grey and red.

It is a fast-drying anticorrosive based on zinc phosphate also suitable for light alloys and iron surfaces in general.

If used on new surfaces, it is advisable to degrease them well before application; if they are old surfaces, it is necessary to brush and remove poorly anchored paint well before applying the product.

The recommended working sequence is as follows

1. brush off all parts of poorly adhering paint, removing them;

2. sand all areas to be painted with fine abrasive paper;

3. wash the entire surface with a cloth soaked in thinner or turpentine;

4. allow to dry;

5. apply one or two coats of Eliomare 135 (oleophenolic rust inhibitor) to ensure remarkable resistance to any type of chemical-physical, industrial, marine, etc. aggression

6. after complete drying (allow at least 48 hours), apply two coats of Eliofinish One Coat enamel in the desired colour.

Yes, by directly applying Eliosteel enamel gel directly onto the rusted surface, Eliosteel enamel gel is a specific and innovative finishing product in the field of rust protection as it stops the corrosion process and ensures a very long cure time. Furthermore, it is possible to achieve high thicknesses without dripping thanks to its controlled thixotropy.

The product indicated is called Eliometal, a water-based, non-film rust converter that eliminates the need for manual sanding as it removes rust by making it react chemically and transforming it into a ferrotannic compound (dark powder to be removed).

Recommended operating sequence for new surfaces where calamine is present

1. facilitate detachment of the oxide layer by applying a first coat of Eliometal converter diluted 50% with water;

2. after 24 to 48 hours, apply the second coat of Eliometal as is.

Recommended operating sequence for old oxidised surfaces

1. remove rust flakes and poorly anchored friable parts with brushes and pressurised water jets;

2. apply one or two coats of Eliometal after moistening the substrate.

Of course, because the term “for outdoors” reported on the packaging indicates the high quality of the product capable of resisting the climatic conditions of the external environment.

Partial masking can hardly be achieved perfectly because it depends on the different compactness of the material used and consequently its degree of absorption.

There are, however, two possibilities, one more costly involving the use of a total skimming plaster and then painting with quartz flour or washable exterior paint;

A partial procedure is possible involving the use of an acrylic primer over the entire surface and two coats of quartz flour Antico Rivestimento Centro Storico; any imperfections will be camouflaged and will only be visible when the light hits.

The optimal solution involves re-plastering.

However, a partial painting (with the use of a plasterboard-type striped bandage) and subsequent total painting of the façade with two coats of New Plastic thick plastic coating with high mechanical and protective properties can be used to seal the substrate.

It is important to carefully assess the extent of the cracks present and use a dovetail rake to open them up further and fill them with a strong, very flexible filler such as Stuck 84 in two or three passes.

After drying, shave the surface by applying a strip of special paper (such as that used for plasterboard joints) over the crack and then paint with Alcalin Resistente Sigillo Oro if you want a highly washable and water-repellent paint with excellent retouching behaviour, or with Bisaten water paint to prevent the formation of mould.

Since this is a lived-in facade, it is essential to use the solvent-based Eliogum Primer fixative which, as such, is capable of dissolving the greasy substances deposited over time. It is also suitable for chalking, dusty surfaces, as well as for consolidating old paints.

Once this is done, the work is completed with the decorative water-based wall finish Antico Copertura Centro Storico made up of finely ground quartz sands, particularly suitable for the restoration of old buildings or new constructions where a coating highly resistant to the most aggressive atmospheric agents and excellent color retention is required.

Applying the solvent-based and breathable Eliogum Antifumo wall paint that easily covers surfaces blackened by soot, smog or hot air.

If the walls concerned are new, we recommend dusting the entire surface before applying the first coat of paint directly.

If, on the other hand, the surfaces have been previously painted, it will be advisable to proceed as follows:

1. remove any poorly anchored residues;

2. fill any imperfections with the special Stuck 81 filling paste filler;

3. touch up the filled areas with a coat of Eliogum Antifumo diluted to 10% with Turpentine or Thinner 622;

4. paint the entire surface white or with Eliolux enamel max 2%

The products of Di Maria Colorificio are the result of continuous and constant research in order to offer solutions that are always cutting-edge and effective.

A greater concreteness to the credibility of the information about our products is also given by the marketing of so-called “certified” products.

Over the years, in fact, Di Maria Colorificio has achieved numerous product certifications.

The Bisaten cycle, a flagship product of the Di Maria paint factory, makes it possible to effectively sanitize mold-contaminated rooms, protecting walls over time. The effectiveness of the Bisaten sanitizing cycle, which involves the use of detergent, fixative and water paint, is confirmed by the guarantee certificate.

Eliover 012, produced by the Di Maria paint factory, is an epoxy enamel approved for the vitrification of containers used for food storage. It is solvent-free and boasts high chemical and abrasion resistance. Approved at the provincial hygiene and prophylaxis laboratory of the province of Milan. Test report no. 103097.

Many products from Maria's Paint Factory comply with the VAA protocol (Paint for Environments with the Presence of Food) ideal for ensuring balanced protection of environments at risk of bacterial growth caused by mold and lichen.

This is a self-control system to ensure the prevention of food contamination hazards. Colorificio Di Maria offers many solutions with appropriate certifications for food environments.

Indoor air emissions are identified and classified according to a scale ranging from A+ (low emissions) to C (high emissions). The A+ label is an important recognition for our work in terms of limiting pollutant emissions of volatile organic compounds. The A+ mark is characterized by high technological innovation, low solvent emission, zero Formaldehyde and high performance.

This special acrylic water-based paint has been designed for the elastomeric encapsulation of asbestos-cement products, in order to prevent the spread of airborne fibres. Its strong biocidal action neutralises and prevents the microbiological deterioration of asbestos-cement surfaces caused mainly by mould, algae, moss and lichens. It also offers considerable resistance to atmospheric agents and ultraviolet rays. The product is certified by the Giordano Institute (test report No. 144147) in accordance with current European regulations and in compliance with the provisions of the Decree of the Ministry of Health of 20/8/1999 relating to the expansion of regulations and technical methodologies for remediation interventions. Test report No. 271699 by the Giordano Institute.